Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

ABOUT US

- 15 experience

- 10000 Square meter production workshop

- 200000 monthly supply capacity

- 201-500 number of workers

Recommended Products

-

-

High Precision Lens

Lenses are used in optical systems for beam convergence, beam expansion, imaging and collimation. According to the structure of the lens, it can be roughly divided into single lens (including: plano-convex, plano-concave, double-convex, double-concave, cylindrical, drum, spherical and other different shapes), cemented lens, combined lens group and other different types.

-

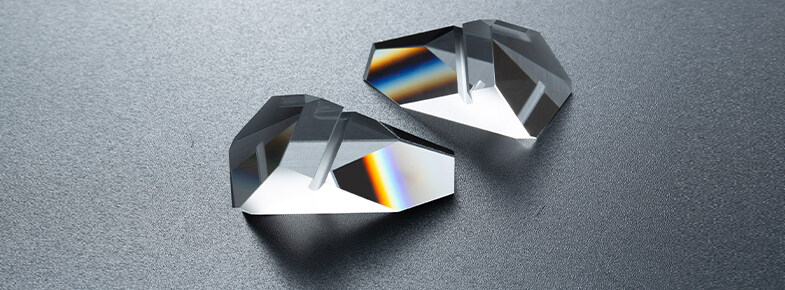

Half Pentaprism

1. Prism angle accuracy: conventional ≤ 3'-6', unconventional ≤ 1'-2', parallel ≤ 0.003mm. Among them, the ridge angle and cube can be controlled to ≤2", and the ridge angle can reach ≤1". 2. Dimensional tolerance: controlled within ±0.02mm. 3. Tower difference: The angle of tower difference is generally controlled at 3′, and the minimum can reach 1′ or better. 4. Surface shape (aperture): mass production can reach λ/4, λ/8, λ/10 or better. 5. The dimensional tolerance of the slot can be controlled to ±0.05mm.